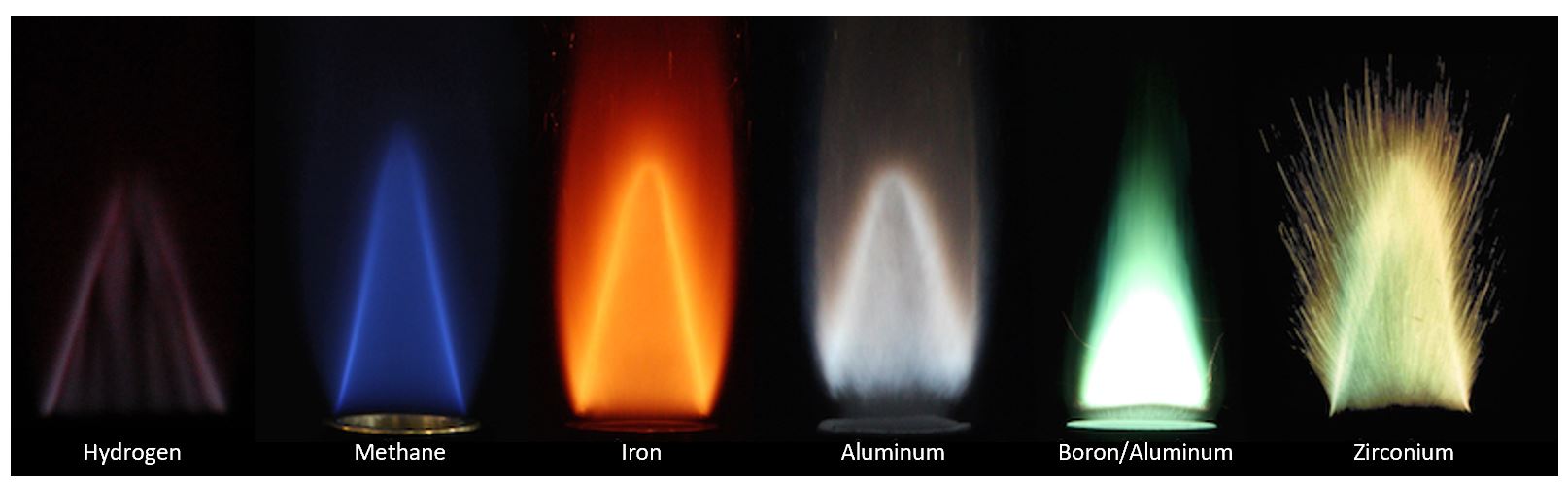

We develop fundamental science and practical applications that address the current climate change challenge. Our current research themes are focused on metal-air combustion, metal-water reaction, and gas-phase combustion.

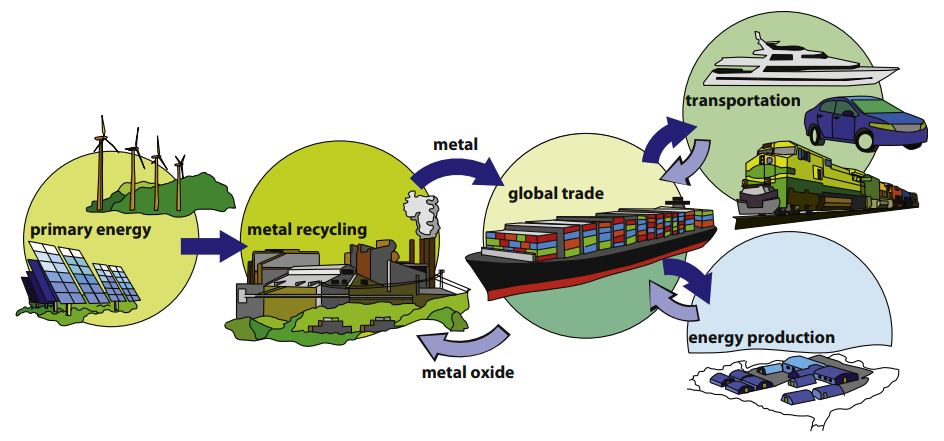

The Cycle of Metal Fuels

The combustion of metal fuels is carbon free as it produces metal oxides. These solid metal oxides can be recycled back into metals using renewable energy (e.g., wind, hydro, etc.), making the whole cycle sustainable.

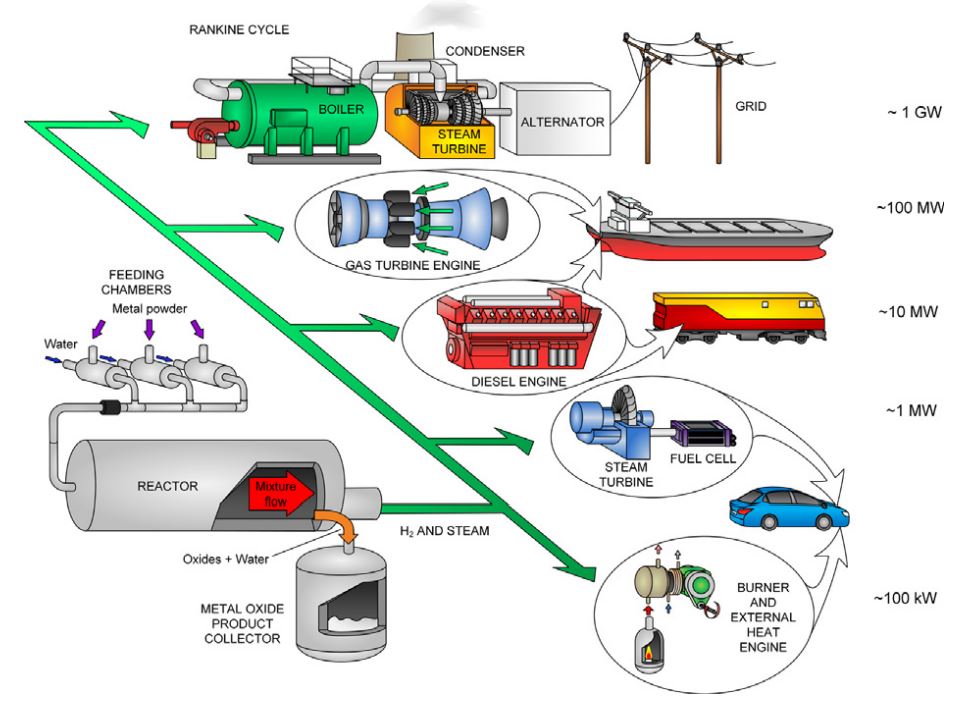

Applications of Metal Fuels

Metals possess high energy densities and can be easily transported, so they are suitable energy carriers. The metal-fuel combustion heat can be used directly for industrial or residential heating and can also power external combustion engines, operating on the Rankine or Stirling cycles.

Science Promotion of the AFL

We are passionate in science promotion. The students at our research group attend various activities such as conferences, SEDTalks to share our research findings to a wide range of audience, from technical experts to the general public.

The Diversity of the AFL Team

Our research group values equity, diversity, and inclusion (EDI). We are proud of having diverse students and researchers from different parts of Canada and around the world to contribute to the solutions to the rising concerns of climate change.